What do a furniture maker in Texas and a frozen pizza manufacturer near Chicago have in common? Both are facing steep fines and penalties for lockout/tagout violations that resulted in worker injuries. OSHA’s lockout/tagout standard establishes the employer’s responsibility to protect employees from hazardous energy sources, such as electrical current, on machines and equipment. Lockout/tagout violations are some of OSHA’s most commonly-cited hazards – and they can have tragic and costly consequences.

Furniture: Sitting on Repeated Violations

In Temple, Texas, a company that designs and manufacturers furniture for customers that include the U.S. military and NASA has been cited for five violations: three repeat violations related to hazardous energy control, and two serious violations for failing to follow lockout/tagout procedures. OSHA investigated the company in April 2021 after an employee suffered a broken finger in a machine. The agency cited the manufacturer for similar violations in 2015 and 2016 and is now proposing nearly $250,000 in fines.

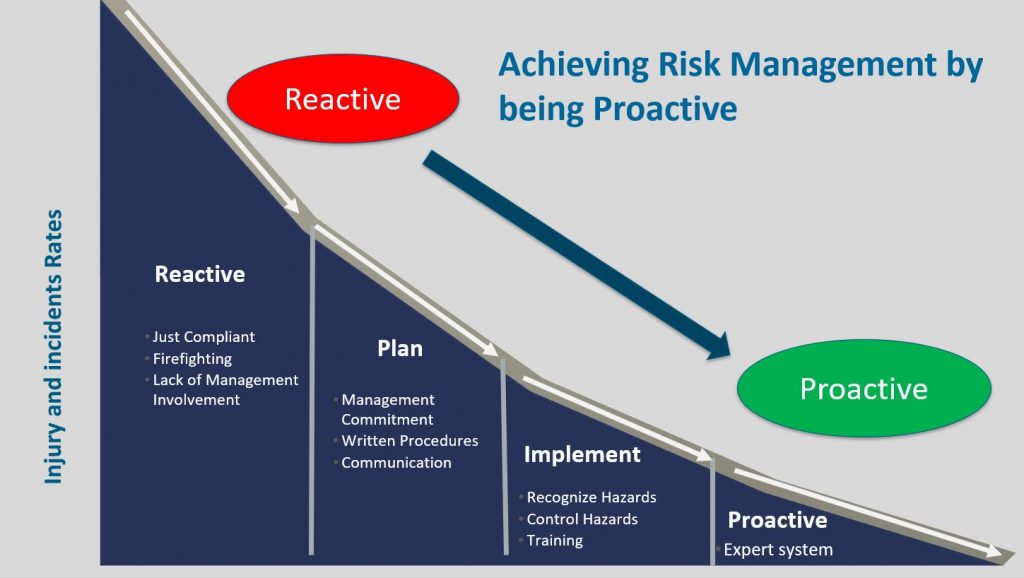

“Employers need to develop and implement machine-specific procedures,” says James Testo, president of EHS Risk Management. “They also need to ensure that employees are trained to follow these procedures as part of a larger energy control program, but one that takes a proactive rather than a reactive approach to safety. Training goes hand-in-hand with recognizing and controlling hazards.”

Frozen Pizza: Delivering Violations Nationwide

In Illinois, an employee at a frozen pizza manufacturer died after being injured while cleaning a machine. A subsequent OSHA investigation determined that the employer failed to implement energy control procedures and that lockout/tagout violations exposed workers to serious hazards. OSHA has issued one willful violation to the manufacturer, which is headquartered out-of-state, and proposed nearly $150,000 in penalties. The company has an extensive history of nationwide violations and been placed in OSHA’s Severe Violator Program.

“This preventable tragedy is another example of why employers must ensure lockout/tagout procedures are in place before allowing workers to clean or operate machinery,” said OSHA Chicago South Area Director James Martineck in Tinley Park. “Employers who fail to follow safety standards and train workers in operating procedures will be held accountable.”

Taking a Proactive Approach to Safety

As the incidents in Texas and Illinois show, failing to take a proactive approach to safety can have tragic and costly consequences. Employers need to follow OSHA’s lockout/tagout standard, but they also need to develop an energy control program that’s not just about writing procedures, but about training employees to recognize and control risks. This requires a leadership commitment and today’s technology.

To learn more about how to take a proactive approach to safety and the technology that you’ll need, download this article from EHS Risk Management.